Print Do’s & Dont’s for Apparel Printing

We want your order to look as awesome as you do! We’ve put together a list of things to consider and things to avoid when preparing your order.

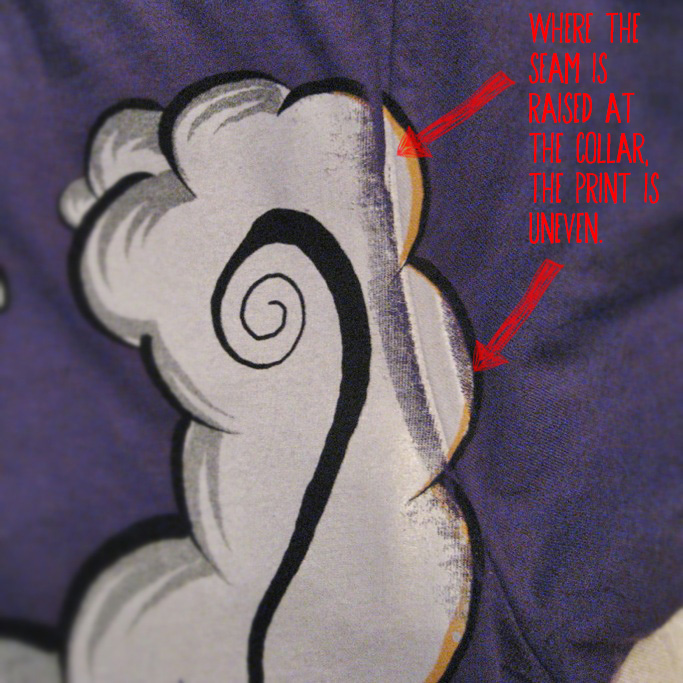

Why Not To Print Over Seams, Pockets or Zippers

To get the best quality print when screen printing, we need as flat of a surface as possible between the pallet (that the garment lays on) and the screen (that holds your design). The fronts and backs of t-shirts are consistently smooth and the same thickness, which allows us to get a perfect print every time. However, when you print over a seam, pocket or zipper, it creates an inconsistency, because these are thicker portions of the garment. When you print over these portions of the garments, it creates a gap in the print where the ink from the screen does not touch the shirt due to the ridge caused by the seam.

We do our absolute best to give you the highest quality print possible, but when a print goes over the seams, we cannot accept responsibility for any negative effects caused by this issue.

Note: For hooded sweatshirts, we do have special pallets that have indentations for the zipper and pocket seams but not every sweatshirt is exactly the same.

NOTE: Any print that goes over a seam will result in imperfections in the print. (Some customers find this effect desirable, but we discourage it and will not be held responsible for misprints).

What Shirts Don’t Work Well With Jumbo Prints

Jumbo prints account for approximately 50% of all orders placed at our shop. People want as big of a print as possible. With standard unisex or mens tees, this is typically not a problem. However, some shirts have issues when printing Jumbo:

- Tank Tops: Most tank tops are low cut at both the neckline and the sleeves. Printing jumbo prints on these garments can cause print defects from printing over the seams.

- V-Necks: The neck line of the v-neck may cut into the design. Please take this into account when you are designing your shirt.

- Youth/Girls Tees: Jumbo pallets are wider than most youth/girls tees. In order to get the youth/girls tee onto the press, it has to be stretched. This can cause several issues: possible ripped shirts, loss of form from stretching past normal means, a distorted image due to stretching the shirt, and the design being cut off the bottom/sides of the shirt.

What Garments Don’t Show Detail Well

With advancements in screen printing (including high mesh count screens and specialty presses) we can recreate a level of detail with t-shirts that was previously unattainable just 5-10 years ago. However, due to the way some garments are constructed, they will not work well with detail. The following is a list of those garments:

- Ribbed Garments

- Canvas Material (Aprons, Bags, etc.)

- Burnout Tees

- Pique Polos

These items do not work well with detail because they are not smooth like standard t-shirts.

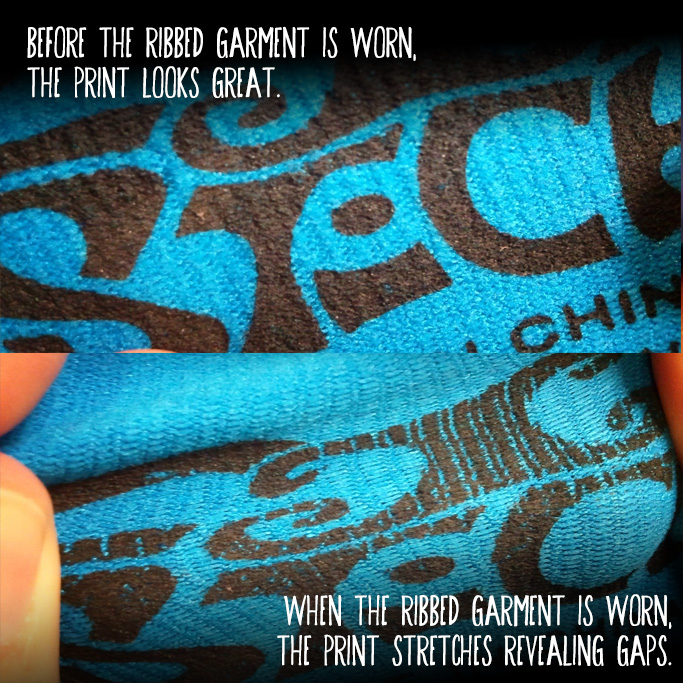

Why Not To Print On Ribbed Garments

Ribbed garments provide the best form fit of all blank shirts as they stretch to meet the size of the individual wearing them. This is great the for final consumer but makes printing on them a problem. When you pull a ribbed garment onto the press, it is not stretched out, so the ink only goes on the top of the ribs. Then, when the shirt is put on, the ink pulls apart, exposing a gap between the ribs that is not printed. We can apply more pressure on the press to try to force the ink into the gaps, but this limits the amount of detail that is actually shown on the garment. Because of these issues, we strongly suggest that you do not print on ribbed garments. Here is an example:

Screen Printing Over Seams

If the design is closer than 1/2″ to the seam, this can cause printing inconsistencies. The seams prevent the screen from being able to lie completely flat on top of the garment when printing. When the screen has to sit over the seams, this is what causes the ink to lay unevenly in that area.

What amount of space should I leave when printing near seams?

It is recommended that you leave at least 1/2″ of space between the edge of your design and any shirt seams.

Can I print over seams?

Printing over seams is not recommended. When you print over seams, a gap is created in the print where the ink from the screen does not touch the shirt due to the ridge caused by the seam. This causes inconsistencies in the print from shirt to shirt which is why we strongly recommend against printing over seams.